Technology Development

Commitment

Basic Research

We always think outside the box to realize innovative ideas by focusing on the foundation of the product, including materials, spinning, and manufacturing processes.

Product Development

However, we have a development attitude that challenges the word "impossible," and we will continue to develop towels that many people demand.

Sustainability

We are committed to a diverse society centered on all energy related to towels, and we will challenge to solve problems as consumers continue to use towels from the time of production.

Process of making towels

Introduction to the various processes involved in towel production.

Here we will introduce the basic steps involved in making a towel.

-

01

Material selection

Select materials suitable for the purpose.

-

02

Spinning

Impurities, etc. are removed and the fibers are twisted to a yarn state. The twisting method and number of twists are adjusted according to the characteristics of the towel.

-

03

Scouring and bleaching

Dirt and impurities are removed to bring out the natural whiteness.

-

04

Dyeing

When dyeing in the yarn state, dyeing is done before weaving the towels.

*If the fabric is dyed after it is woven, it is called "post-dyeing." -

05

Warping

The warp and pile yarns are wound to the required number and length. Accuracy and technical skill are required because the yarns must be wound with uniform tension.

-

06

Weaving

Typical looms include the dobby loom, which can weave plain colors and simple patterns, and the jacquard loom, which can weave complex patterns, and they are used depending on the design.

-

07

Treatment

The glue applied for weaving towels is removed, dyed, dried, and so on.

-

08

Sewing / Processing

The hems and selvedge edges of the towels are sewn, and then post-processing such as embroidery is carried out. Finally, each towel is inspected by hand and checked for needles before being shipped.

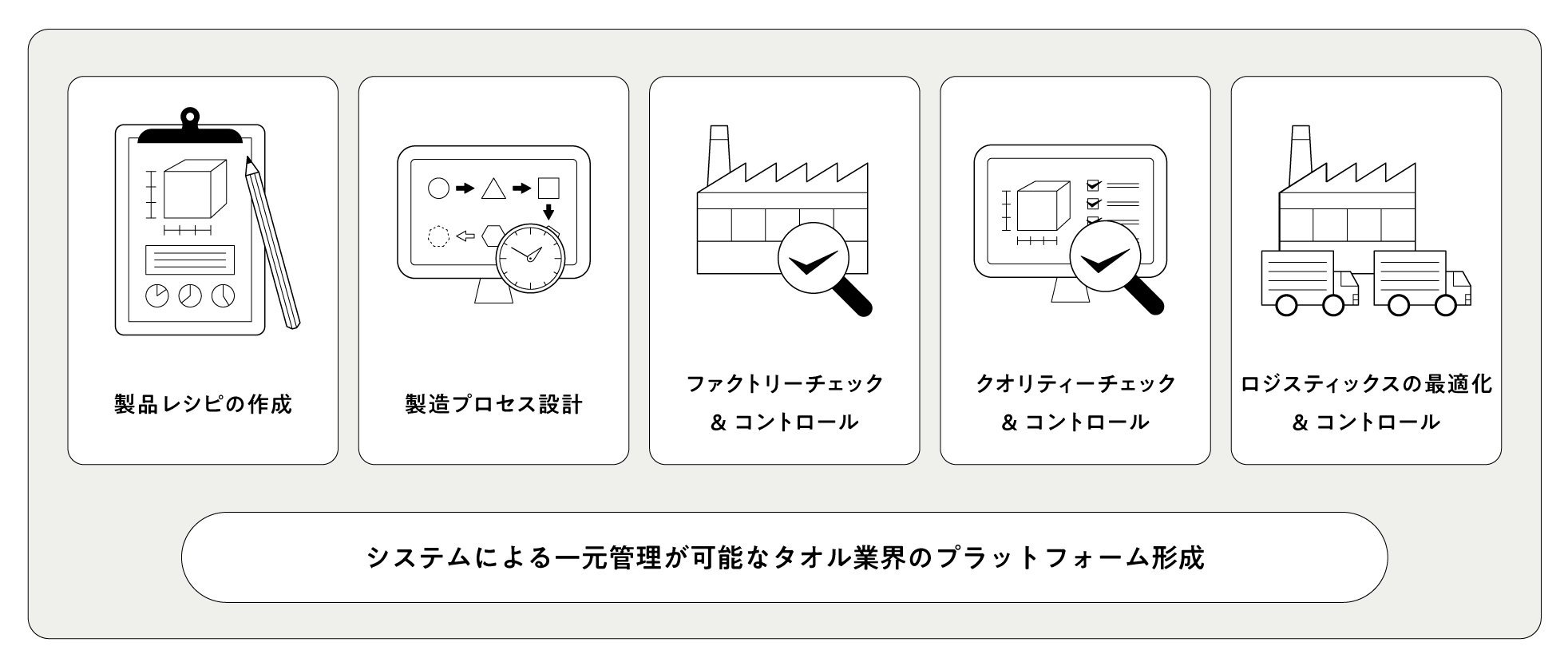

IOPMS

Izawa Original Production Management System

We have established a unique systematized management system from the creation of product blueprints to the delivery of the product to the customer, achieving quality that exceeds that of conventional towel manufacturing. It has also enabled overwhelming innovation in manufacturing costs, allowing us to provide unparalleled performance.